Machine Technical Parameters and Introduction:

Bottle table:

Model:PT-2

Material:Stainless steel 304

Size:600*600*1000mm

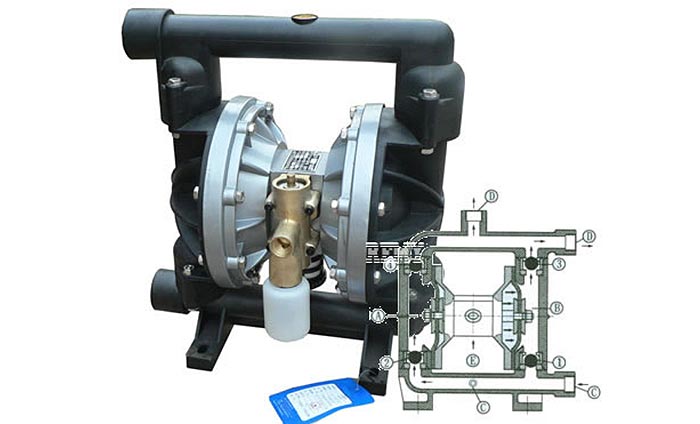

Diaphragm pump:

Flowing:3T/H

Liquid temperature:

Normal temperature type: -15℃~+70℃

Hot water type: +70℃~+110℃

Highest ambient temperature: +40℃

Max.operation pressure :10 bar

Max.inlet pressure is limited by max.operation pressure

Running speed: 2900rounds/min

2500BPH 500ML Shampoo Filling Machine:

Type: ZSP-12A/2000 (With 12 filling heads )

1.1 Suitable material: Oil, daily chemicals, and something that very viscous.

1.2 This shampoo filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

1.3 Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position.

1.4 When close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution.

1.5 Convenient adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment.

Technical Parameter:

|

No. |

Item |

Technical Data |

|

1

|

Capacity |

2500BPH for 500ml bottles |

|

2

|

Filling Range |

100ml-2000ml |

|

3

|

Accuracy |

±0.5% |

|

4

|

Power |

3KW |

|

5

|

Voltage |

3 Phase 380V 50HZ |

|

6

|

Weight |

1200KG |

|

7

|

Dimension |

2500*1500*2300MM |

Main Configuration:

|

1

|

Touch Screen |

WEINVEIW |

Taiwan |

|

2

|

PLC |

Mitsubishi |

Japan |

|

3

|

Sensor |

OPTEX |

Japan |

|

4

|

Solenoid Valve |

SHAKO |

Taiwan |

|

5

|

Cylinder |

AIRTAC |

Taiwan |

|

6

|

Servo motor |

Panasonic |

Japan |

|

7

|

Frequency Converter |

Schneider |

France |

|

8

|

Button |

Schneider |

France |

|

9

|

Relay |

Omron |

Japan |

|

10

|

Magnetic switch |

AIRTAC |

Taiwan |

Part of Liquid Filling Machine:

Contact part material : SS 316 , other machine parts : SS 304

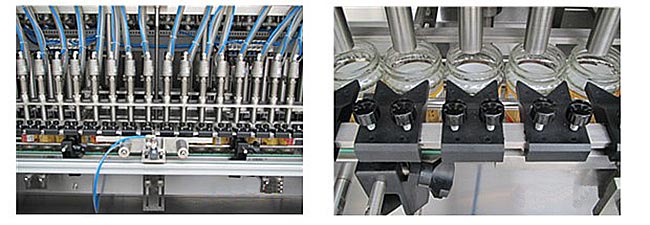

Filling heads:

Tank connect part :

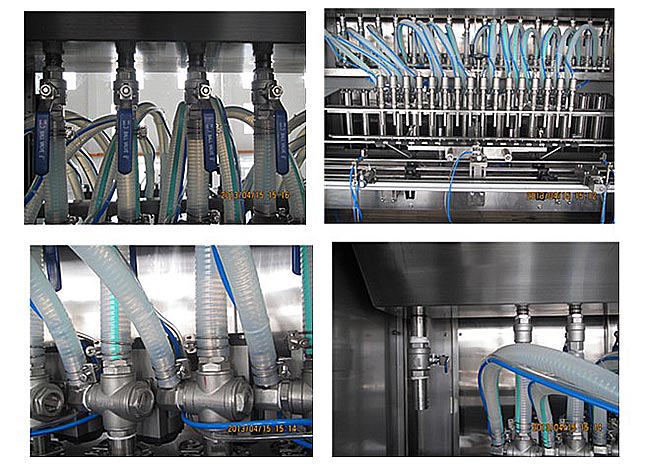

Inside back of Shampoo Filling Machine:

Outside back of Automatic Shampoo Filling Machine:

Spare parts list:

|

Item |

Specification |

Quantity |

|

Piston ring seal |

Φ66 |

6 sets |

|

Cylinder gasket |

Φ80*3.1 |

6 sets |

|

Joint |

APL-6-01 |

6 pieces |

|

Duct clamp |

Φ30 |

6 sets |

|

Duct clamp |

Φ40 |

6 sets |

|

Synchronous belt |

1 piece |

|

|

Screw |

M5 M6 M8 |

2 sets |

|

Nut |

M5 M6 M8 |

2 sets |

|

Proximity switch |

PR12-4DN |

1 piece |

|

Potentiometer |

10KΩ |

|

|

Electromagnetic valve |

BM520 |

|

|

Electromagnetism switch |

AIRTAC |

1 piece |

|

Tools kit |

1 set |

|

|

Tools box |

1 piece |

|

|

Instruction |

1 piece |

Full-automatic Vertical Capping Machine:

Full-automatic Vertical Capping Machine Brief Introduction:

- This automatic inline capping machine has four speed-adjustable

motors which separately used in lid-arranging, sleeve lid, lid-capping and conveying, in the capping process can be automatic arrange lid, automatic sleeve lid, automatic capping.

- This machine has a high automation degree, good steadiness,

convenient adjustment, changing bottle sizes or lid, needn’t any parts, only need some adjustments.

Technical Parameter:

|

No. |

Item |

Technical Data |

|

1

|

Capacity |

4000-5000BPH |

|

2

|

Cap’s Diameter |

Ø15~Ø60mm |

|

3

|

Bottle’s Diameter |

Ø35~Ø140 |

|

4

|

Power |

1.5KW |

|

5

|

Voltage |

220V 50HZ |

|

6

|

Weight |

750KG |

|

7

|

Dimension |

2000*900*2000MM |

Main Configuration:

|

1

|

Button |

Schneider |

France |

|

2

|

Frequency Converter |

Schneider |

France |

|

3

|

Air Device |

AIRTAC |

Taiwan |

|

4

|

Twisting Motor |

HUANGYAN |

China |

|

5

|

Cap-sort Motor |

HUANGYAN |

China |

|

6

|

Bottle-fixer motor |

HUANGYAN |

China |

|

7

|

Conveyor motor |

HUANGYAN |

China |

|

8

|

Speed reducer |

JIAOXING |

China |

Automatic Adhesive Labeling Machine (two side):

This machine is suitable for side labeling, especially on the cylindrical, flat, square, rectangular and elliptical bottles you can reference following pic 1and 2. The machine is economical and easy to operate. The performance is stable with a level off. The system easy changeover based the requirement.

Key Features:

- Labeling speed up to 180 bottle/min ( according to the length of label )

- PLC Control System which is easy to control

- Simple Straight Forward Operator Controls

- On-Screen trouble description which is easy to solve

- Stainless Frame

- Open Frame design, easy to adjust and change the label

- Variable Speed with stepless motor

- Label Count Down (for precise run of set number of labels) to Auto Shut Off

- Stamping Coding Device attached

Specifications:

Labeling Speed: 80 BPM– 330 ML

60 BPM – 1000 ML

- Bottles size : customized based on the requirements

- Label size: customized based on the requirements

- Dimensions: 2400mm×1350mm×1500 mm ( Length × Width × Height )

- Weight: 500kg

- Electrical Requirements:

— Power:500W, Voltage: 220V, Frequency: 50-60HZ(Optional)

- Working direction: Left → Right (or Right → Left)

Industry Type(s)

- Cosmetic /personal care

- Household chemical

- Food & beverage

- Pharmaceuticals

|

Model |

Specification |

Brand |

Manufactory |

|

Side Labeling Machine |

HMI |

Touch screen (DELTA) |

DELTA Electronic |

|

CPU |

SAMSUNG |

SAMSUNG |

|

|

PLC |

DELTA |

DELTA Electronic |

|

|

Signal connecting wire |

Delta |

DELTA Electronic |

|

|

Converter |

Delta |

DELTA Electronic |

|

|

Bottle inspection sensor |

AUTONICS |

AUTONICS Company |

|

|

Label inspection sensor |

SUNX |

SUNX Ltd. Japan |

|

|

Series motor |

JSCC |

JSCC Motor |

|

|

Motor speed control |

JSCC |

JSCC Motor |

|

|

Step motor |

STEP |

Step Co.Ltd. |

|

|

Stainless steel |

304 |

PUXIANG STEEL |

|

|

Steel frame |

Bao steel in Shanghai |

||

|

Series axletree |

Ha Industry |

Automatic code sprayer:

1. Function

1) Single nozzle can spray two lines of information.

2) Height of characters (1.8mm) (2.5mm) (3.2mm) (3.9mm) (5.8mm).

3) Many languages: Latin, Arabia, Japanese, Chinese and Korean.

4) Production date, future date or best-before date, time, shifts and automatic counting 2 calculators.

5) Bar codes: 2/5 code 39 code.

6) Automatic start and off

7) Interface operation: 128×32 LCD screen menu key and LED indicator light.

8) Manual keyboard: 240×128 LCD screen WYSIWYG information display and drop down menu.

9) More than 99 pieces of information are in store.

10) Interface of Many languages: More than 20 languages are optional such as English, French, Italian, German, Russian, Japanese, Chinese, Korean.

2. Ink system

1) Self checker and conk out test.

2) Automatic ink-chroma control and ink-line speed control system.

3) Self-clean.

4) Nozzles are automatically gotten through.

5) Ink and addictive are sealed in the packed box. ( 0.42 liter or 0.8 liter).

3.Machine specification

1) Weight: 8.3 kilograms.

2) Temperature rang of working environment: 5℃ to 45℃.

3) Elevation of spraying heads and machine body: -1.5 meters/+2meters.

4) Humidity: 10% to 90% no frozen.

5) Voltage: 110V (+/-20%), 220 (+/-20%), can be changed automatically.

6) Power: 50VA, frequency ranges from 45 Hz to 65 Hz.

7) Safeguard grade:IP54.

Collecting table:

Model:PT-2

Material:Stainless steel 304

Size:600*600*1000mm

Case sealer:

Auto folding for top lid ensures smooth and suitable sealing motions. The entire sealing operation is automatically performed, providing elegant outlook and labor-saving, the machine can be operated together with an automatic packaging line.

Technical Parameters:

|

Model |

FXJ5050Z |

|

Sealing Capacity |

Max.720 units per hour |

|

Used Adhesive tape |

OPP(Width 38-60mm) |

|

Voltage, Power |

Three-phase Voltage:380V |

|

Air Source |

0.5-0.6Mpa(5-6Kg/cm²) |

|

Air Consumption |

100L/min |

|

Machinery Demission |

1210×900×1650 |

|

Machinery Weight |

About 250Kg |

|

Applicable Demission of Paper Box |

Length 200-600(mm) |

|

Width 80-500(mm) |

|

|

Height 100-380(mm) |

Conveyor:

1.Side panel: 304 stainless steel wire-drawing sheets, thickness are 2.5mm.

2. Power: Jiebrand Hangzhou.

3. Supporting leg: 304 stainless steel pressing structure

4.Trunking and cover: 304 stainless steel, thickness is 1mm.

5.Chain plate: Domestic high-quality plastic chain plate, polyoxymethylene (POM).

6. Bearing housing: 304 stainless steel cage.

Low Pressure Air Compressor:

Air compressor is the air source for transfer oil,carrying out the process of compressing air from atmosphere to the required pressure.

The post 2500BPH 500ML Shampoo Filling Line appeared first on king machine.