Hand Washing Filling Line

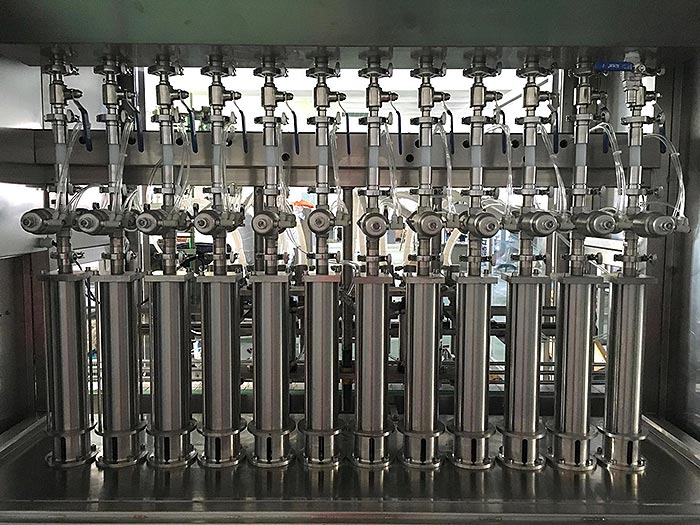

1. 8 heads Piston Filling Machine( Servo ) with pump

Brief Introduction

•Contact part material : SS 316 , other machine parts : SS 304

•Suitable material: Oil, jams, daily chemicals, and something that very viscous.

•This hand washing filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity transduction and pneumatic action.

•Accurate measurement: adopt servo control system, ensure the piston can always reaches constant position.

•When close to target filling capacity can be applied to realize speed slow filling, prevent the liquid spill bottle mouth cause pollution.

•Convenient adjustment: replacement filling specifications only in touch screen can be changed in parameters, and all filling first change in position, fine-tuning dose it in touch screen adjustment.

Hand Washing Filling Machine Technical Parameter:

|

No.

|

Item

|

Technical Data

|

|

1

|

Capacity

|

2500-3000BPH

|

|

2

|

Filling Range

|

50ml-2000ml

|

|

3

|

Accuracy

|

±0.5%

|

|

4

|

Power

|

1.1KW

|

|

5

|

Voltage

|

3 Phase 380V 50HZ

|

|

6

|

Weight

|

1000KG

|

|

7

|

Dimension

|

2000*1500*2300MM

|

Main Configuration:

|

No.

|

Item

|

Brand

|

Origin

|

|

1

|

Touch Screen

|

WEINVEIW

|

Taiwan

|

|

2

|

PLC

|

Mitsubishi

|

Japan

|

|

3

|

Sensor

|

OPTEX

|

Japan

|

|

4

|

Solenoid Valve

|

SHAKO

|

Taiwan

|

|

5

|

Cylinder

|

AIRTAC

|

Taiwan

|

|

6

|

Servo motor

|

Panasonic

|

Japan

|

|

7

|

Frequency Converter

|

Schneider

|

France

|

|

8

|

Button

|

Schneider

|

France

|

|

9

|

Relay

|

Omron

|

Japan

|

|

10

|

Magnetic switch

|

AIRTAC

|

Taiwan

|

Spare parts list:

|

No.

|

Item

|

Specification

|

Quantity

|

|

1

|

Piston ring seal

|

Φ66

|

6 sets

|

|

2

|

Cylinder gasket

|

Φ80*3.1

|

6 sets

|

|

3

|

Joint

|

APL-6-01

|

6 sets

|

|

4

|

Duct clamp

|

Φ30

|

6 sets

|

|

5

|

Duct clamp

|

Φ40

|

6 sets

|

|

6

|

Synchronous belt

|

–

|

1 piece

|

|

7

|

Screw

|

M5 M6 M8

|

–

|

|

8

|

Nut

|

M5 M6 M8

|

–

|

|

9

|

Proximity switch

|

PR12-4DN

|

1 piece

|

|

10

|

Potentiometer

|

10KΩ

|

2 sets

|

|

11

|

Electromagnetic valve

|

BM520

|

2 sets

|

|

12

|

Electromagnetism switch

|

AIRTAC

|

1 piece

|

|

13

|

Tools kit

|

–

|

1 set

|

|

14

|

Tools box

|

–

|

1 piece

|

|

15

|

Instruction

|

–

|

1 piece

|

2. Automatic Vertical lid-revolver

Instruction

Full-automatic vertical lid-revolver is specially designed for clean products . The machine’s appearance is artistic and scholar, flexible, quick lid-revolving speed, high conformity rate, it may suit for the different bottle shape’s lid-revolving for foodstuff, pharmacy, daily chemical industry, pesticide and cosmetics. The four units of speed-adjustable motors is separately used in lid-feeding, bottle-clamping, conveying and lid-revolving, the machine has a high automation degree, good steadiness, convenient adjustment, changing bottle sizes or lid, needn’t any parts, only need some adjustments (for example, link with the lid-feeder, may automatically feed lids),This machine can be used for irregular caps, like caps with nozzles,etc.

Technological parameters:

●Bottle diameter : Φ35mm- Φ100mm

●Bottle height : 80mm-250mm

●Suitble Cap Diameter : Φ20mm-Φ55mm

●Power : 2kw

●Power supply : AC220V ; 50Hz (or according to client’s voltage requirement)

●Tightening Speed : 2500-3000 Bottles/Hour

●Machine Weight : 480KG

Machine Dimension (L×W×H) : 1000mm x 700mm x 1800mm

3. Automatic adhesive labeling machine(Double sides)

Main parameters

●Machine Description : Labeler 50 BPM Enlarge Type

Machine Model : SL-250

●Feeding System : Conveyor + Wheels (Screws optional to the shape of bottles)

●Controlling System : LCD & PLC (7 sets of memories to set)

●Bottle Size : 0.1-1.5L

●Coding System : Stamping on color belt (3 Rows Max, 12 characters Max per row)

●Machine Size : 2050*1400*1250mm

●Remark : Customization is also available According the customer sample the machine height and width might be changed .

Main components brand:

|

S.N.

|

Name

|

Remark

|

|

1

|

Touch screen

|

WEINVIEW

|

|

2

|

PLC

|

Panasonic

|

|

3

|

Transducer

|

Schneider

|

|

4

|

Light fiber switch

|

Panasonic

|

|

5

|

Reducer

|

Hangzhou, JIE brand

|

|

6

|

Motor

|

Shanghai

|

4. Bottle table

Parameters

●Model : PT-2

●Material : Stainless steel 304

●Size : 600*600*1000m

5. Flat convey

Parameters :

●Side panel : 304 stainless steel

●Panel thickness : 2.5mm.

●Motor : Hangzhou Jie brand

●Supporting leg : SUS 304 pressing structure

●Trunking and cover : SUS 304

●Cover thickness : 1mm.

●Chain plate : POM

Bearing housing : SUS 304

The post Hand Washing Filling Line appeared first on king machine.